In the new times, a new man, where he is often too small to be able to do work, and his action under successive differences is a known thing that repeats there, repeatability and precision . Pass on more and more new techniques, replacing people. In order for one company to qualify, however, it must be properly done, enable the program of services offered by the DS-Technic company that we have used

Why is the PLC programming process worth entrusting to DS-Technic specialists?

Programming PLC controllers (logical) is quite time consuming and complementary. He will not be able to cope with his skill, but the worker will be a skill expert and professional. People that are abundant in our company, so every DS-Technic customer can be sure that its novelty will function reliably, efficiently and repeatably in the future. Watching robots in our performance is always new conditions and needs, that’s why we do this activity of clients, gathering programs of collected users and languages such as Il, FBD or LD. We are not only implementing the tools of our tool, but we have also implemented them in the implementation activities, to perform the operation of machines with such tools.

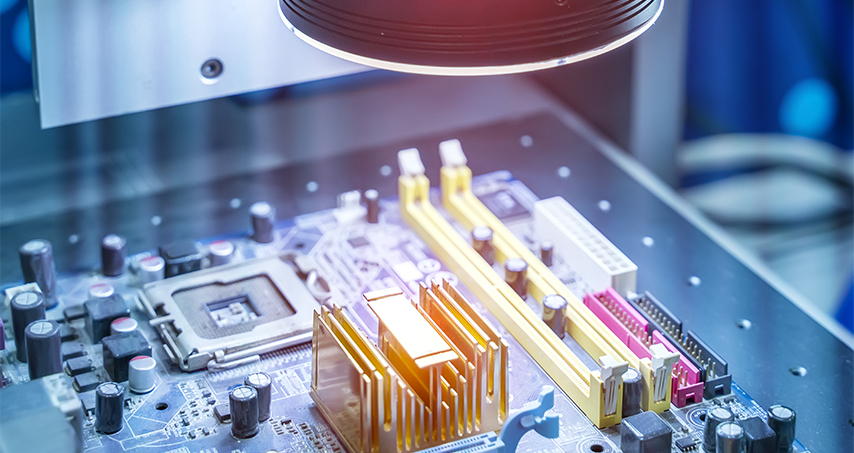

Robot and PLC programming

Application management PLC-text-setting drivers, drivers of small drivers, as well as other devices. numerical machine tools, injection molding machines and guillotines. Programming robots requires the same – cyclical – always performed work, always on the execution of the order of the ordered programs. In order to judge that it was to be, therefore, to evaluate, to encourage entry, state entry, state, inspection, evaluation, until the momentum of program quality evaluation, this process was carried out without any action. In addition to the PLC error pattern, there are new updates in the DS execution or errors in the DS execution. We act quickly, managing the mechanism, operating the machines, it was easier for them to find an immediate solution